The farm has soils typical of the region – acidic brown earth with Clonroche and Old Ross series characteristics.

As Philip explained: “It’s ground that can be challenging at times. We’ve always been Kverneland when it comes to ploughs – two EGs before this one, as far back as I can remember.”

Why they chose the 3300 S

That loyalty did not mean the Kehoe’s were not looking to improve. When they saw the Kverneland 3300 S advertised, the higher leg clearance caught their eye. It was enough to ask for a demo – and that demo proved decisive.

“The cover crop was probably over 1m high,” Philip says.

“The demo had trash boards instead of skimmers and it just buried everything. There wasn’t a piece left. We were really impressed.”

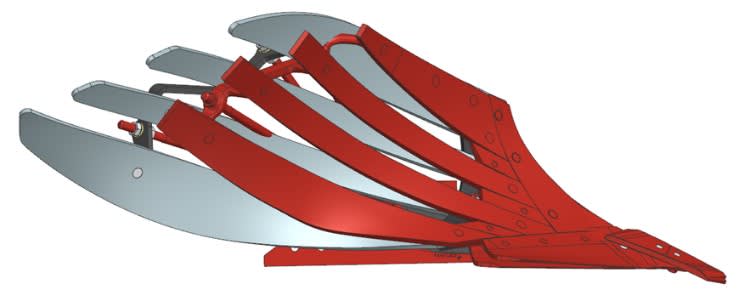

The 3300 S’s new aero-profile legs were a big part of that performance. Designed with an 80cm leg height, they offer excellent clearance for heavy residues, manure or tall cover crops - helping prevent blockages even when ploughing deep. The special aero shape improves soil flow, while the robust, pre-formed design reduces welds for greater strength. And thanks to their hollow, lightweight construction, they need less pulling power, cutting fuel use on every pass.

All-new No. 40 bodies for easier pulling

The Kehoes originally ordered their new 3300 S with the standard No. 30 slatted bodies, but they had heard about the new No. 40 bodies coming and decided to wait.

Francis Kehoe said: “We wanted them for the better inversion and the easier pulling. We’ve been growing cover crops for four or five years now, and you can get very heavy crops if you get them in early. This plough can bury it all in one pass, no problem. Before, we used to have to disc the cover crop twice just to cut it up enough to plough.”

Kverneland’s Body No. 40 is designed for just these conditions. It is a longer, slimmer design that reduces pulling forces – even in heavy or sticky soils – and suits large tractor tyres. The shape delivers a better inversion and a tighter finish for improved drainage and soil structure.

Philip said; “The 40s were definitely easier to pull than the 30s. They turn the ground better on the side and you save time. With the higher legs – these are 80s instead of 70s – you’ve loads more room for trash to flow through without blockages.”

The Kehoes also like the fact the new bodies are designed to leave a tight, well-inverted furrow even at lower speeds, giving them flexibility across different soil conditions and jobs.

More features for less effort

One big change was opting for trash boards – that demo plough that convinced them came with trash boards instead of the usual skimmers.

According to Francis: “We weren’t sure if they’d suit all conditions. So we ordered a set of skimmers with it as well. They’re sitting in the garage still – so far the trash boards have been perfect.”

Beyond the bodies and trash boards, the Kehoes have found the whole 3300 S setup much easier to use.

“It’s our first plough with a hydraulic rear wheel,” Francis said.

“At headlands you just pull the lever in the cab, lift the wheel – no messing. You’re not finishing in a furrow that’s too deep at the ends.”

The new headstock and transport system also made an impression.

Philip explained: “It’s a lot safer on the road, It’ll steer itself behind you, you can drop the wheel and let it follow. No need to carry it all on the lifts.”

Dealer support from Donohoes

Philip and Francis both credit Donohoes of Enniscorthy, Co. Wexford for the smooth changeover.

Francis said: “When the plough arrived new, both the rep from Kverneland Ireland and Donohoes came out to help us set up. They showed us all the little bits. It was very easy. And they’re great to deal with. Any question, they’re there. No bother at all.”

Philip added: “We’ve also just bought a 5m Kverneland Enduro cultivator, replacing an older 3m Kverneland CLC. from Donohoes in Enniscorthy too. It’s brilliant for grubbing headlands before sowing – especially for early barley. With the 5m, we can keep ahead of the seeders without holding them up. The hydraulic depth and top link adjustments are really handy, and the build quality seems just as good as the old CLC that’s served us over decade.”

Ready for the seasons ahead

Looking ahead, they’re also keen to make the most of Kverneland’s XHD tungsten-tipped wearing parts.

“We haven’t tried them yet,” Philip said.

“But the claim is 10 times the life. With the short windows we get for sowing, if it saves even half an hour of downtime swapping tips, that’ll be well worth it.”

Francis added: “It’s been a big improvement for us. We’re getting more done in a day, using less diesel, no blockages.

“We’d have no hesitation recommending the 3300 S to any tillage farmer.”