ts-drill

Seeder | Tine Seeder

The Kverneland tine seeder – the cost-efficient alternative.

The Kverneland tine seeder ts-drill has been designed to work in extreme conditions i.e. in dry, stony or wet soil. Established in conventional tillage after the plough, it is also perfect for reduced tillage. Straight coulter tips are available to meet the different requirements

The advantages of this Tine Seeder

- Fits to conventional & conservation tillage systems

- Ready for extreme conditions

- Excellent ground contour following

- Operator-friendly with excellent overview

- Close centre of gravity for saving fuel

Description

The Kverneland ts-drill carries out cultivation and sowing in one pass. The 5 rows of passive tools are set in offset configuration and allow operation at high working speed. The large hopper capacity of 1700 litres (1350 litres plus 350 litres extension) reduces the set-up time. Due to the optimized position of the hopper, the centre of gravity is close to the tractor.

In a single pass, the auto-reset tines take care of tilling and seeding, which in turn reduces soil compaction whilst saving fuel and time. Due to the floating wing sections of the ts-drill with 5.00m and 6.00m working width, the ts-drill works fine on slopes or uneven ground. The central position of the landwheels within the main frame adapts perfectly to the ground contours thus ensuring an even depth control.

Operator-friendly Kverneland ts-drill: easy adjustment and high-performance seeding

The Kverneland ts-drill is designed with a strong focus on operator-friendly handling and easy adjustment. Known for its versatility and wide range of equipment, the ts-drill seed drill offers farmers a reliable, high-performance solution for modern crop establishment systems.

Quick and easy adjustment

With user-friendly controls and clear scales, operators can easily set the machine depth and return to previous settings without complications. The horizontal alignment of the seed drill is conveniently monitored by a simple indicator at the hopper. The seeding depth adjustment requires no tools, thanks to a spacer system that controls the central depth wheels. This allows rapid switching from shallow oilseed rape drilling to deeper wheat seeding, saving valuable time during busy seasons.

Ergonomic design and easy access

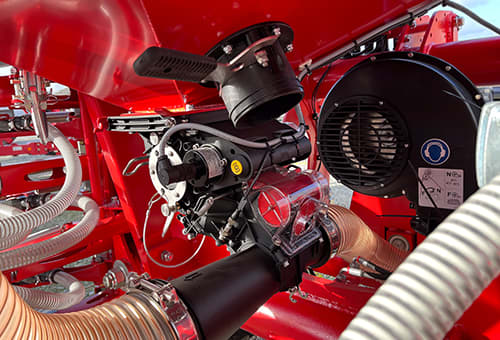

The patented lateral position of the ELDOS metering device ensures ergonomic access for quick and precise calibration. In addition, the electronic low-level sensor, adjustable outside the hopper at three filling levels, reliably monitors a wide range of seeds, from small oilseed rape to larger grains, ensuring consistent performance.

A smart alternative for crop establishment

Combining ease of use, high efficiency, and flexible seeding options, the Kverneland ts-drill stands out as a powerful alternative among crop establishment systems, helping farmers achieve precise, efficient, and reliable seeding results.

Highlights

- Versatile: ready for conventional and conservation tillage systems

- Ready for extreme conditions as humid soil or stony grounds

- Reliable performance due to well-proven ts-drill tines of high quality spring steel & Kverneland leaf-spring auto-reset overload protection

- Excellent ground countour following due to the wheels mounted in the centre

- Operator-friendly with excellent overview

- Complete control of the machines from the tractor cab on the move

- Environment-friendly with a close centre of gravity saving fuel

Features

Features

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

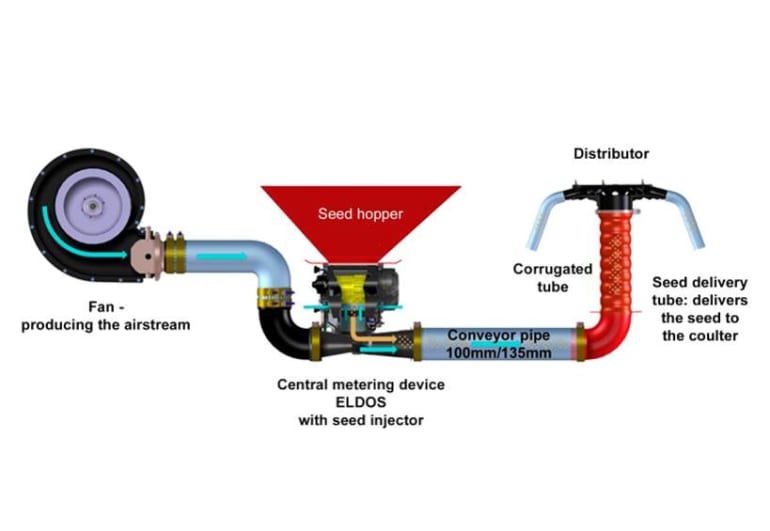

- The metering device ELDOS accurately measures the required volume of seed by the distinctive rotor and discharges it into the seed injector where is is mixed with the air stream and then conveyed through the diffusor tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

- The intelligent off-set arrangement of the seeding tines across five rows allows the ts-drill to place the seeds accurately into the seedbed, even in conditions with high amounts of crop residues. With one tine in front of each land wheel and the symmetrical distribution of the rear row of tines, the ts-drill ensures consistent seed depth and optimal levelling. The ts-drill is available with tine spacings of 12.5cm or 15cm.

- The seeding tines of the ts-drill are made of high-quality spring steel and are equipped with the Kverneland leaf-spring auto-reset overload protection.

- As an alternative to the standard straight coulter tine, the ts-drill can be equipped with narrow tines featuring an XHD carbide tip. These narrow tines minimise soil disturbance while providing sufficient strength to break up the surface, enhancing the ts-drill’s versatility for both conventional and conservation tillage systems. The XHD carbide tip extends the tines’ service life.

- The tines are designed with a patented seed outlet that eliminates screws in the tube ensuring uniform seed depth placement, even in extremely humid and sticky soils.

With the patented outlet it is also easier to change the share tip

Equipped with the largest profile wheels of all machines in its class (11.5/80-15.3 10PR), the ts-drill offers significant advantages. The large diameter wheels of the ts-drill run smoothly and easily. The tyre pressure (approximately one bar) ensures the “footprint” of the machine being significantly reduced. Deep wheelings are avoided whilst the seed bed is protected against compaction.

The seeding depth is adjusted, without the need of any tools by using spacers on the wheels mounted in the centre of the main frame. This guarantees that the ts-drill will adapt perfectly to the ground contours and the sowing depth is simply more precise.

- Effective seed covering after sowing is ensured by the twin row precision following harrow section as standard equipment.

- The special design of the tines allows even high quantities of damp plant residues to pass through the harrow without blocking.

- The harrow pressure and its aggressiveness can be adjusted via the spring pressure adjustment and the angle of the harrow bar.

- As an option, the ts-drill can be equipped with a one-row V-harrow and press wheels. This offers the possibility of applying additional pressure. If the seed press wheels are not required due to very humid conditions, they can be completely lifted.

For the electronic control of the ts-drill, a whole range of steering systems is available

Focus 3

Focus 3 is the terminal steering the e-bas system which features hopper low level sensor, various tramline systems, information about ha, km/h monitoring of fan speed, pre-emergence marker, seed rate adjustments. Focus 3 is not ISOBUS compatible.

Tellus 700

Single Screen, Multiple Options Tellus 700 simplifies precision farming with smart features, custom mapping, and a user-friendly design. With ISOBUS compatibility and flexible packages, it boosts in-field efficiency and control.

Tellus 1200

Multiple Screens, Even more Options

Tellus 1200 the 12-inch universal Terminal offers intelligent hopper monitoring and precise variable rate application for fertiliser and seed. With an intuitive interface, multi-screen functionality, and GEOCONTROL compatibility, it delivers smart, all-in-one control beyond standard tractor systems.

IsoMatch FarmCentre

The best overview in farm management.

- The intelligent off-set arrangement of the seeding tines across five rows allows the ts-drill to place the seeds accurately into the seedbed, even in conditions with high amounts of crop residues. With one tine in front of each land wheel and the symmetrical distribution of the rear row of tines, the ts-drill ensures consistent seed depth and optimal levelling. The ts-drill is available with tine spacings of 12.5cm or 15cm.

- The seeding tines of the ts-drill are made of high-quality spring steel and are equipped with the Kverneland leaf-spring auto-reset overload protection.

- As an alternative to the standard straight coulter tine, the ts-drill can be equipped with narrow tines featuring an XHD carbide tip. These narrow tines minimise soil disturbance while providing sufficient strength to break up the surface, enhancing the ts-drill’s versatility for both conventional and conservation tillage systems. The XHD carbide tip extends the tines’ service life.

- The tines are designed with a patented seed outlet that eliminates screws in the tube ensuring uniform seed depth placement, even in extremely humid and sticky soils.

With the patented outlet it is also easier to change the share tip

Equipped with the largest profile wheels of all machines in its class (11.5/80-15.3 10PR), the ts-drill offers significant advantages. The large diameter wheels of the ts-drill run smoothly and easily. The tyre pressure (approximately one bar) ensures the “footprint” of the machine being significantly reduced. Deep wheelings are avoided whilst the seed bed is protected against compaction.

The seeding depth is adjusted, without the need of any tools by using spacers on the wheels mounted in the centre of the main frame. This guarantees that the ts-drill will adapt perfectly to the ground contours and the sowing depth is simply more precise.

- Effective seed covering after sowing is ensured by the twin row precision following harrow section as standard equipment.

- The special design of the tines allows even high quantities of damp plant residues to pass through the harrow without blocking.

- The harrow pressure and its aggressiveness can be adjusted via the spring pressure adjustment and the angle of the harrow bar.

- As an option, the ts-drill can be equipped with a one-row V-harrow and press wheels. This offers the possibility of applying additional pressure. If the seed press wheels are not required due to very humid conditions, they can be completely lifted.

- The metering device ELDOS accurately measures the required volume of seed by the distinctive rotor and discharges it into the seed injector where is is mixed with the air stream and then conveyed through the diffusor tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

For the electronic control of the ts-drill, a whole range of steering systems is available

Focus 3

Focus 3 is the new terminal steering the e-bas system which features hopper low level sensor, various tramline systems, information about ha, km/h monitoring of fan speed, pre-emergence marker, seed rate adjustments. Focus 3 is not ISOBUS compatible.

IsoMatch Tellus GO

The multifunctional one-screen terminal has been developed for fast and simple control of all ISOBUS implements, giving the farmer a ‘customer made’ experience as it suits all needs for plain and efficient handling of farming machinery and tasks. IsoMatch Tellus GO is the farmer’s first step into Precision Farming. With the easy to use application, IsoMatch GEOCONTROL, it is possible to boost efficiency and save time and costs. The application includes Manual Guidance, Section Control and Variable Rate.

IsoMatch Tellus PRO

- Two ISOBUS interfaces in one terminal

- Multifunctional ergonomic design

- ISOBUS Shortcut Button (ICB)

With this new terminal you can work all the way as a PRO. The maximum working range for the task controller IsoMatch GEOCONTROL is increased from 2 km to maximum 10 km from the starting point. Thus even extremely big fields are handled in a full professional way. The new high brightness screen increases operator comfort. Visibility is increased during the day and dimmed to just a glowing display in dark conditions.

Technical specifications

Technical specifications

Download brochure| Model | ts-drill 4800 | ts-drill 5000 | ts-drill 5600 | ts-drill 6000 | |

|---|---|---|---|---|---|

| Working width (m) | 4.80 | 5.00 | 5.60 | 6.00 | |

| Transport width (m) | 3 | 3 | 3 | 3 | |

| No. of coulters (12.5cm distance) | 38 | 40 | - | 48 | |

| No. of coulters (15.0cm distance) | 32 | - | 40 | 40 | |

| Min. power requirement (HP/KW) | 120 / 88 | 125 / 92 | 130 / 96 | 130 / 96 | |

| Weight (kg) | 1,805 | 1,850 | 1,930 | 1,980 | |

| Hopper capacity (l) | 1,350 | 1,350 | 1,350 | 1,350 | |

| Hopper extensions (max. 1700l) (l) | Option (350 l) | Option (350 l) | Option (350 l) | Option (350 l) | |

| Hopper cover plus gas pressure regulator | Standard | Standard | Standard | Standard | |

| Quick emptying chute | Standard | Standard | Standard | Standard | |

| Low level sensor | Standard | Standard | Standard | Standard | |

| Lighting hopper inside | Option | Option | Option | Option | |

| Mechanical fan drive | Option | Option | Option | Option | |

| Hydraulic fan drive | Standard | Standard | Standard | Standard | |

| Fan speed control | Standard | Standard | Standard | Standard | |

| ELDOS electric metering device incl. 5 rotors | Standard | Standard | Standard | Standard | |

| Metering device control | Standard | Standard | Standard | Standard | |

| Seed rate adjustment | Standard | Standard | Standard | Standard | |

| Seed quantity (min. / max.) (kg/ha) | 1-400 | 1-400 | 1-400 | 1-400 | |

| Tramlining system with e-bas or e-com eletronic steering | Option | Option | Option | Option | |

| Shut-off valves for tramlines | Option | Option | Option | Option | |

| Pre-emergence marker | Option | Option | Option | Option | |

| Half-width shut-off | Option | Option | Option | Option | |

| Radar speed sensor | Standard | Standard | Standard | Standard | |

| Calibration kit | Standard | Standard | Standard | Standard |

Technical specifications

Technical specifications

Download brochureModel |

ts-drill 4800 |

ts-drill 5000 |

ts-drill 5600 |

ts-drill 6000 |

Working width (m) |

4.80 |

5.00 |

5.60 |

6.00 |

Transport width (m) |

3.00 |

3.00 |

3.00 |

3.00 |

No. of coulters (12.5cm distance) |

38 |

40 |

- |

48 |

No. of coulters (15.0cm distance) |

32 |

- |

40 |

40 |

Min. power requirement (HP/KW) |

120 / 88 |

125 / 92 |

130 / 96 |

130 / 96 |

Weight (kg) |

1,805 |

1,850 |

1,930 |

1,980 |

Hopper capacity (litres) |

1,350 |

1,350 |

1,350 |

1,350 |