KVERNELAND iXter B

Sprayer | Mounted sprayer

The power of technology!

The Kverneland iXter B mounted sprayer is the result of years of research and development in close collaboration with farmers. The iXter B sprayer is designed with focus on ease of use, intelligent electronics and environmental protection.

The advantages of this Mounted sprayer

- EasyHitch - Ingenious locking system

- iXspray for an user friendly operation

- iXclean Pro fully automatic valve management system

- iXflow-E high pressure recirculation system

- Boom Guide: automatic boom height control system

- TwinFill: automatic filling program for iXter B-iXtra

Description

The intelligent electronics guarantee an user friendly operation of the iXter B in combination with innovative features, like iXclean, iXflow-E, iXflow-Pulse (Pulse Width Modulation system), ErgoDrive headland managment and Boom Guide. With the EasySet control panel, filling the sprayer is easy, clean and safe. Compact design with a centre of gravity close to the tractor, reduce need for lifting capacity and improve overall stability and driving comfort. The EasyHitch quick hitch system is an ingenious locking system which secures connection of the sprayer closest to the tractor. The ENFO functions are included for automatic priming and rinsing. Additional operator convenience can be achieved with iXclean Comfort semi-automatic or iXclean Pro fully automatic, electric valve management system. The iXter B is available up to an 1800l nominal tank capacity in combination with two different boom types: the HOSA aluminium spray boom (15m) and the HC steel boom (18-30m).

Highlights

- The EasySet control panel boosts productivity by its intuitive operation: easy, clean and safe filling of the sprayer.

- Compact design with a centre of gravity close to the tractor for an optimal weight balance.

- The EasyHitch quick hitch system with an ingenious locking system makes life simple.

- iXspray means an intuitive user interface and user friendly operation that ensures that spraying is done in the most easiest and efficient way.

- Optional available with iXclean Comfort for semi-automatic control or iXclean Pro fully automatic valve management system.

- Possible in combination with iXflow-E - high pressure recirculation system with individual electric nozzle control to increase crop quality and save costs.

- Possible in combination with iXflow-Pulse, pulse width modulation system (for HC18-30m boom).

- Possible with Boom Guide sensor technology: perfect guidance in many challenging field conditions.

Features

Features

Your Sprayer, Always Connected with Kverneland Sync

Kverneland Sync ensures your ISOBUS sprayer remains fully connected, facilitating continuous data transfer to IsoMatch FarmCentre and Kverneland ServiceCentre. Sync enables real-time monitoring, efficient task management, and remote diagnostics, allowing technicians to swiftly analyze and resolve electronic issues, minimizing downtime and maintaining application consistency.

Optimised Taks Management and Field Documentation

With Kverneland Sync, users have seamless access to key spraying data through IsoMatch FarmCentre, which supports comprehensive task documentation, application tracking, and detailed performance metrics. This connectivity aids in planning, reporting, and accurate record-keeping, allowing users to view spray rates, patterns, and field coverage for enhanced field management.

Enhanced Security and Connectivity

Kverneland Sync also provides geofencing features with real-time location tracking. The Sync accumulator ensures continued traceability, even when the sprayer is disconnected from the tractor. Kverneland Sync and IsoMatch FarmCentre create an integrated solution that optimises efficiency and ensures traceability. By collecting data from the sprayer we are able to analyse the best spraying conditions and empowers precision and efficiency of the next spraying operation.

Only spray when it is needed

Increase the environmental protection by only spray when it is needed with the new SpotSpray application within the iXspray software on the IsoMatch Tellus terminal in combination with the Kverneland sprayer !

Optimal Crop Protection

The SpotSpray application is based on a predefined prescription map with zero application rates. These prescription maps can be made in a similar way as the Variable Rate Application (VRA) prescription maps, in combination the SpotSpray application the sprayer shuts on and off. This is done based on the predefined sections in the control terminal and can even be done with normal section valves on the sprayer. Only designated spots are sprayed, which is particularly helpful when targeting weed spots, thistles, wet areas, non-germinated areas and areas with soil problems.

Another benefit is that based on the area of the spots in the VRA map, it is easy to see exactly how much spray liquid is required in the sprayer. Capacity is also increased as more hectares or fields can be covered with one tank of spray liquid.

With a relatively small investment in the SpotSpray license on the IsoMatch Tellus terminal, the return on investment is high, due to saving time and money. With this, spot spraying becomes accessible for all famers and contractors.

With SpotSpray costs can be saved by reducing the spray liquid to be used and preserve healthy crop from unnecessary treatment. This also means less crop damage.

Dual Tank Strategy

The innovative iXtra concept offers much more than just extra tank volume. In combination with the iXter B mounted sprayer, the iXtra front tank provides a total volume of around 3000 litres, making the iXter-iXtra combination a serious alternative to a self propelled sprayer. With tractors able to carry much higher loads on their rear linkages, the need for ballast weight on the front of the tractor is essential. With a nominal volume of more than 1100 litres, the iXtra is that front end weight, adding stability to your tractor, but only when needed!

- One-tank approach: filled with spray liquid it boosts overall tank capacity by 60%.

- Two-tank approach: filled with two different tank mixes, the front and rear tanks can be used as two independent spray tanks.

- Reservoir approach: filled with clean water the iXtra front tank can be used as a reservoir for later use, for example in another field or crop.

Easy to Fit, Simple to Unhitch

The iXtra front tank used the functions of the iXter B sprayer when filling and spraying. This avoids the need for a separate induction hopper or spray pump for the front tank. Without a front PTO shaft or hydraulic hoses, hitching and unhitching the iXtra is extremely simple: it uses only two hoses with KAMlock connections and an electric cable - it really is that simple!

-

Electrical Level Indicator

The electrical level indicator on the front tank provides actual tank volume to a spraying computer as well as via the external display on the Easy Set control panel of the iXter B mounted sprayer.

-

iXclean Basic

ENFO priming and rinsing is standard on all Kverneland spray computers. Before spraying starts the spray lines are filled with chemicals exactly up to the nozzle by automatic shut off. After finishing or interruption, crop protection agents are automatically flushed out of the spray lines with a minimum of clean water consumption. This ENFO technology optimizes filling and cleaning of the spray lines. Accurate application, no waste of products and saving water are the benefit for the environment.

-

iXclean Comfort

iXclean Comfort is a semi-automatic valve control system. The combination of an electrical level indicator and suction valve provides operator comfort and accuracy; automatic filling stops when the programmed level is reached, and remote control of all ENFO rinising and priming functions are carried out from the cab! Simple prime the spray lines before you start and rinse them afterwards.

-

iXclean Pro

iXclean Pro is an advanced solution with fully automatic, electric valve management. It means all functions can be controlled from the cab. Switching between filling, agitation, spraying, diluting, priming, rinsing and tank cleaning, is extremely easy: just push the button! In addition iXclean Pro offers also a fully automatic multi-step rinsing and cleaning program with triple dilution for the entire sprayer. Pushing one button a comprehensive cleaning process including all lines will start. It is so thorough, that residue levels after automated cleaning are below 1%.

-

iXflow-E

iXflow-E is the high pressure recirculation system with electric nozzle control. There is a free circulation of chemicals with a return of spray liquid back to the tank as spraying stops. This means there is no sedimentation in the spray lines and no dead ends for spraying or cleaning, even when the boom is in vertical position. During spraying each section gets under pressure from both ends of the spray lines, so the operator can immediately start spraying without any pressure drop. It is easy for the operator to program the number and size of sections which fits the best to their requirements and field situations.

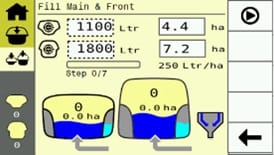

Automatic filling an iXter B-iXtra sprayer combination

Kverneland TwinFill is a combined filling functionality for the iXtra front tank in combination with the iXter B rear mounted sprayer.

Always the perfect concentration

TwinFill is an automatic filling program that lets the operator fill his product in one go, for both the front and rear tank, without the disadvantage of unknown mixing time. The software takes care that the spray liquid is split and transferred to the front and rear tank with the correct volume and equal concentration. After, both tanks are filled with clean water to the required level, the same concentration is reached in both tanks. TwinFill is especially beneficial for medium sized arable farmers, vegetable farmers and contractors in mixed farming areas. The operator can simply fill all of the products in one step to the total required tank volume of the two tanks together or just enter the number of hectares to be sprayed, without having to measure all of the products twice and in different amounts and fill the tanks separately! With TwinFill the operator can immediately start the spray job, because the mixture in both tanks is perfectly diluted and ready for use - and also from start to finish for the complete spray job. There is also no waste of clean water or spray liquid, because it is exactly calculated upfront how much water or spray liquid is needed.

Multi-Tank-Management

The iXter B-iXtra combination still keeps its distinctive feature to have a multi-tank usage with two different spray mixes in front and rear tank for different applications or for storage of clean water for later use or to prepare another mixture at another moment at another place.

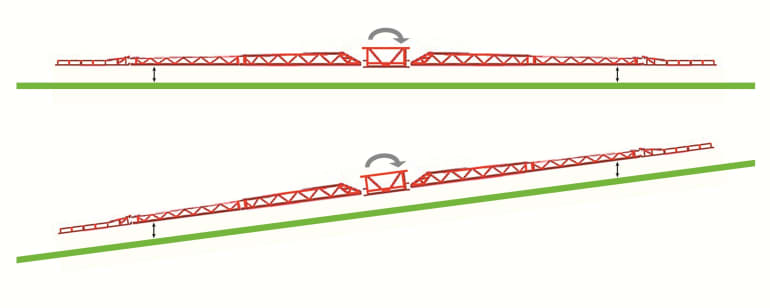

HC 18-20-21-24-27-28-30m Vertical Folding Steel Boom

- The HC boom is the multi-talented boom in the steel boom range. The triangular steel construction and the unique anti yaw system allow high speed even in very difficult conditions. The HC boom is giving you the functionalities for one side folding, symmetrical reduction and asymmetrical reduction depending of the choice for the electric hydraulic command.

HOSA 15m "Z" Folding Aluminium Boom

- The HOSA spray boom is a unique boom of the aluminium boom family having an advanced Z-folding principle: the lateral movement enables you to quickly reduce boom width and pass obstacles in the field. The aluminium profile is designed for maximum resistance. No welding provides remarkable strength, the anodised hardened surface protects against scratches and corrosion.

-

Full Integration Concept

Nobody would expect all these functions so easily to hand. Better protection and integration is simply not possible. iXter B is setting a new standard!

-

Easy Set Control Panel

The Easy Set control panel makes life easy by its intuitive operation. The controls are separated to a suction and pressure side. The valves are well protected behind the door: this keeps your operational area free of dirt and pesticides.

-

Easy Hitch Makes Life Easy

There is enough space to connect the PTO shaft and the hydraulic and electric cables. An ingenious locking system secures the machine and shows the operator it has connected correctly.

-

Easy Operation

The graduated chemical inductor with a capacity of 30 litres is mounted on rails and fully integrated in the frame. In storage position the inductor is sealed against the top plate and no cover is needed. The rotating canister cleaning nozzle releases the water when pushed downwards. The circular rinsing system is no add on: it is part of the design! The standard return flow agitation with its unique agitation tube keeps the tank mixture agitated. The turbo agitation system (optional) allows powerful mixing during preparation of the mixture. This is especially helpful when powders are used or after sedimentation during a longer period of interruption.

iXspray - user interface

The Kverneland mounted sprayer is 100% ISOBUS compatible as standard, which means easy plug and play with the IsoMatch Tellus GO+ or PRO or any other AEF certified terminal. The innovative iXspray hardware and software with intuitive touch interface guarantees an user friendly operation of the sprayer. iXspray is full of nice features to make the operators life easy, save time and avoid mistakes in a busy working season, for example pre-sets for spray jobs and boom configuration can be configured easily.

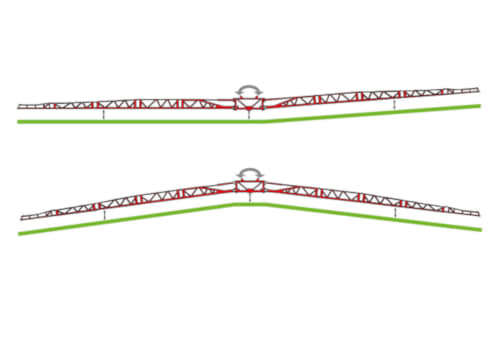

Boom Guide

Boom guide is an automatic boom height control system that helps the operator to maintain your chosen spraying height. Ultrasonic sensors control the sprayer's hydraulics to guide the boom.

Sensors with Hybrid Mode as standard

This unique sensor technology, provides excellent guidance in many different and challenging field conditions and crops. The hybrid mode not only measures the distance to the plant (upper growth), it also measures the distance to the ground or bottom parts of growth at the same time. There are three different modes:

- Soil mode: the sensors only see the bottom. The soil remains representative.

- Crop mode: the sensors only see the crop. In a closed crop the sensors continue to automatically follow the crop (top).

- Hybrid mode: the sensors see the crop and the soil. The sensors follow the soil surface and the crop. When the crop is uneven, an uniform crop is virtually determined. Used in unclosed or uneven crops.

The advantage is a perfect boom guidance at higher speed and a total respect of the optimal nozzle distance to the crop, which result in highest efficiency of the application and reducing drift to a minimum level.

Boom Guide ComfortActive

The two ultrasonic sensors, with integrated roll sensors on the boom, can control the spray height via the central slope correction and boom lift functions. A proportional hydraulic valve is steering the central, hydraulic slope correction cylinder. This cost-effective system is suited to gentle slopes, uneven crop conditions and lower driving speeds.

Boom Guide Pro

This advanced system uses three ultrasonic sensors to control left- and right-hand boom sections independently for the ultimatic guidance in the most challenging field conditions. It can deliver positive and negative lateral movement on each side of the boom to follow the contours in every situation!

Boom Guide ProActive

The system proactively reacts on boom movement and controls both the central and independent slope correction, as well as boom lift functions to guide the boom over the crop canopy, soil surface or a combination of both modes.

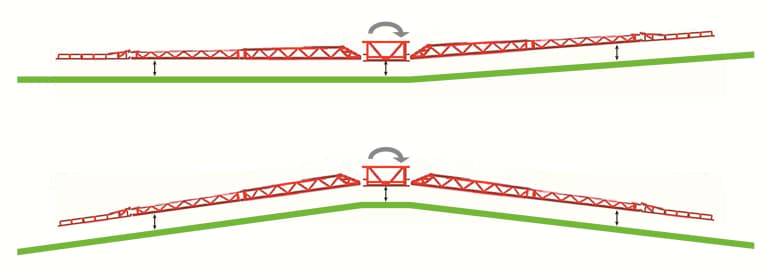

iXflow-Pulse - Pulse Width Modulation system - creates the most effective agronomical spraying due to an optimal balance between droplet size, crop coverage and water use, also under changing conditions of speed or application rate. iXflow-Pulse is available for the iXter B mounted sprayer range in combination with the HC18-30 metre spray boom.

Optimal droplet size for maximum efficiency

iXflow-Pulse is creating a flexible and fast adjustable opening and closing time of the nozzles. When driving faster the opening time will become longer. When driving slower the opening time gets shorter, but by using the iXflow-Pulse the right droplet size will be kept.

Stable spraying pressure

Precision spraying is all about the right spraying pressure in combination with the nozzle to get the right droplet size. iXflow-Pulse (Pulse Width Modulation) takes care of a stable spraying pressure over a wide speed range during variation in application rate. For example, during speed variation at start/stop on headlands, slowing down during turning or when driving and spraying up or down the hill. Another benefit is that the pressure and flow can be adjusted separately as well as during operation. One nozzle can be used for a wider range of applications, which means less changes of nozzles required, saving time and increasing efficiency. There is also the ability to use lower pressure with the same nozzle in challenging or windy conditions. iXflow-Pulse improves the coverage of the spray target in combination with a minimalisation of drift and evaporation.

iXcurve - even dosing in curves

When spraying in different field conditions, for example driving in curves or passing obstacles, the left and right boom has a different speed and this can cause overdosing or under dosing. With the feature called iXcurve, which is included in the iXflow-Pulse system, the modulating spray pulses by adapting the opening and closing time to compensate the speed difference, resulting in an evenly covered crop or surface with the right amount of spray liquid.

HC 18-20-21-24-27-28-30m Vertical Folding Steel Boom

- The HC boom is the multi-talented boom in the steel boom range. The triangular steel construction and the unique anti yaw system allow high speed even in very difficult conditions. The HC boom is giving you the functionalities for one side folding, symmetrical reduction and asymmetrical reduction depending of the choice for the electric hydraulic command.

HOSA 15m "Z" Folding Aluminium Boom

- The HOSA spray boom is a unique boom of the aluminium boom family having an advanced Z-folding principle: the lateral movement enables you to quickly reduce boom width and pass obstacles in the field. The aluminium profile is designed for maximum resistance. No welding provides remarkable strength, the anodised hardened surface protects against scratches and corrosion.

ErgoDrive Headland Management System

ErgoDrive headland management is optionally available for the iXter B mounted sprayer in combination with the HOSA 15 metre and HC 18-20-21 metre spray booms. The HC 24-30 metre spray boom range is standard equipped with ErgoDrive which assists the operator on the headland turns. It is activated by simply switching ON or OFF and ErgoDrive controls all the necessary actions, while the operator can focus on driving safely. When Section Control is used during an u-turn on the headland, the last section will stop spraying (automatically be de-activated) and ErgoDrive starts automatically. After the u-turn ErgoDrive should manually be activated again with the ON button.

Only spray when it is needed

Increase the environmental protection by only spray when it is needed with the new SpotSpray application within the iXspray software on the Tellus 700 and Tellus 1200 terminal in combination with the Kverneland sprayer !

Optimal Crop Protection

The SpotSpray application is based on a predefined prescription map with zero application rates. These prescription maps can be made in a similar way as the Variable Rate Application (VRA) prescription maps, in combination the SpotSpray application the sprayer shuts on and off. This is done based on the predefined sections in the control terminal and can even be done with normal section valves on the sprayer. Only designated spots are sprayed, which is particularly helpful when targeting weed spots, thistles, wet areas, non-germinated areas and areas with soil problems.

Another benefit is that based on the area of the spots in the VRA map, it is easy to see exactly how much spray liquid is required in the sprayer. Capacity is also increased as more hectares or fields can be covered with one tank of spray liquid.

With a relatively small investment in the SpotSpray license on the IsoMatch Tellus terminal, the return on investment is high, due to saving time and money. With this, spot spraying becomes accessible for all famers and contractors.

With SpotSpray costs can be saved by reducing the spray liquid to be used and preserve healthy crop from unnecessary treatment. This also means less crop damage.

The DAT camera technology on the Kverneland sprayer range is a precision tool which supports farmers and contractors in patch spraying and with that a reduction of spray liquid.

The DAT Ecopatch recognises and categorises weeds in fields with wheat, cereals and oil seed rape. When weeds are recognised by the camera, a signal is sent to the Kverneland field sprayer and the appropriate nozzles are activated, up until a speed of 10 km/hr.

The system is built on pragmatism, relying on the agronomic principle of weeds growing in patches, which means a cost-effective solution.

Using the DAT Ecopatch on a Kverneland sprayer is easy. Just activate the system by clicking a button on the Tellus 700 or Tellus 1200 or any other AEF certified terminal and the combination is ready to go. Automatically, the weed will be recognised and the nozzles are turned on and off.

The data, such as as-applied data and weed heat maps will be directly available and can be used directly in combination with for example IsoMatch FarmCentre for further analysis.

With the DAT camera technology on a Kverneland sprayer savings on spray liquid up to 58%* can be reached. Additionally, the non-sprayed areas will preserve healthy crop from unnecessary treatment, which means less crop damage and another benefit is the increased capacity, as more hectares or fields can be covered with one tank of spray liquid.

Inquire today what the DAT system can do for you.

*2024 DAT trials in canola

HC 18-20-21-24-27-28-30m Vertical Folding Steel Boom

- The HC boom is the multi-talented boom in the steel boom range. The triangular steel construction and the unique anti yaw system allow high speed even in very difficult conditions. The HC boom is giving you the functionalities for one side folding, symmetrical reduction and asymmetrical reduction depending of the choice for the electric hydraulic command.

HOSA 15m "Z" Folding Aluminium Boom

- The HOSA spray boom is a unique boom of the aluminium boom family having an advanced Z-folding principle: the lateral movement enables you to quickly reduce boom width and pass obstacles in the field. The aluminium profile is designed for maximum resistance. No welding provides remarkable strength, the anodised hardened surface protects against scratches and corrosion.

-

Full Integration Concept

Nobody would expect all these functions so easily to hand. Better protection and integration is simply not possible. iXter B is setting a new standard!

-

Easy Set Control Panel

The Easy Set control panel makes life easy by its intuitive operation. The controls are separated to a suction and pressure side. The valves are well protected behind the door: this keeps your operational area free of dirt and pesticides.

-

Easy Hitch Makes Life Easy

There is enough space to connect the PTO shaft and the hydraulic and electric cables. An ingenious locking system secures the machine and shows the operator it has connected correctly.

-

Easy Operation

The graduated chemical inductor with a capacity of 30 litres is mounted on rails and fully integrated in the frame. In storage position the inductor is sealed against the top plate and no cover is needed. The rotating canister cleaning nozzle releases the water when pushed downwards. The circular rinsing system is no add on: it is part of the design! The standard return flow agitation with its unique agitation tube keeps the tank mixture agitated. The turbo agitation system (optional) allows powerful mixing during preparation of the mixture. This is especially helpful when powders are used or after sedimentation during a longer period of interruption.

-

Electrical Level Indicator

The electrical level indicator on the front tank provides actual tank volume to a spraying computer as well as via the external display on the Easy Set control panel of the iXter B mounted sprayer.

-

iXclean Basic

ENFO priming and rinsing is standard on all Kverneland spray computers. Before spraying starts the spray lines are filled with chemicals exactly up to the nozzle by automatic shut off. After finishing or interruption, crop protection agents are automatically flushed out of the spray lines with a minimum of clean water consumption. This ENFO technology optimizes filling and cleaning of the spray lines. Accurate application, no waste of products and saving water are the benefit for the environment.

-

iXclean Comfort

iXclean Comfort is a semi-automatic valve control system. The combination of an electrical level indicator and suction valve provides operator comfort and accuracy; automatic filling stops when the programmed level is reached, and remote control of all ENFO rinising and priming functions are carried out from the cab! Simple prime the spray lines before you start and rinse them afterwards.

-

iXclean Pro

iXclean Pro is an advanced solution with fully automatic, electric valve management. It means all functions can be controlled from the cab. Switching between filling, agitation, spraying, diluting, priming, rinsing and tank cleaning, is extremely easy: just push the button! In addition iXclean Pro offers also a fully automatic multi-step rinsing and cleaning program with triple dilution for the entire sprayer. Pushing one button a comprehensive cleaning process including all lines will start. It is so thorough, that residue levels after automated cleaning are below 1%.

-

iXflow-E

iXflow-E is the high pressure recirculation system with electric nozzle control. There is a free circulation of chemicals with a return of spray liquid back to the tank as spraying stops. This means there is no sedimentation in the spray lines and no dead ends for spraying or cleaning, even when the boom is in vertical position. During spraying each section gets under pressure from both ends of the spray lines, so the operator can immediately start spraying without any pressure drop. It is easy for the operator to program the number and size of sections which fits the best to their requirements and field situations.

Boom Guide

Boom guide is an automatic boom height control system that helps the operator to maintain your chosen spraying height. Ultrasonic sensors control the sprayer's hydraulics to guide the boom.

Sensors with Hybrid Mode as standard

This unique sensor technology, provides excellent guidance in many different and challenging field conditions and crops. The hybrid mode not only measures the distance to the plant (upper growth), it also measures the distance to the ground or bottom parts of growth at the same time. There are three different modes:

- Soil mode: the sensors only see the bottom. The soil remains representative.

- Crop mode: the sensors only see the crop. In a closed crop the sensors continue to automatically follow the crop (top).

- Hybrid mode: the sensors see the crop and the soil. The sensors follow the soil surface and the crop. When the crop is uneven, an uniform crop is virtually determined. Used in unclosed or uneven crops.

The advantage is a perfect boom guidance at higher speed and a total respect of the optimal nozzle distance to the crop, which result in highest efficiency of the application and reducing drift to a minimum level.

Boom Guide ComfortActive

The two ultrasonic sensors, with integrated roll sensors on the boom, can control the spray height via the central slope correction and boom lift functions. A proportional hydraulic valve is steering the central, hydraulic slope correction cylinder. This cost-effective system is suited to gentle slopes, uneven crop conditions and lower driving speeds.

Boom Guide Pro

This advanced system uses three ultrasonic sensors to control left- and right-hand boom sections independently for the ultimatic guidance in the most challenging field conditions. It can deliver positive and negative lateral movement on each side of the boom to follow the contours in every situation!

Boom Guide ProActive

The system proactively reacts on boom movement and controls both the central and independent slope correction, as well as boom lift functions to guide the boom over the crop canopy, soil surface or a combination of both modes.

Dual Tank Strategy

The innovative iXtra concept offers much more than just extra tank volume. In combination with the iXter B mounted sprayer, the iXtra front tank provides a total volume of around 3000 litres, making the iXter-iXtra combination a serious alternative to a self propelled sprayer. With tractors able to carry much higher loads on their rear linkages, the need for ballast weight on the front of the tractor is essential. With a nominal volume of more than 1100 litres, the iXtra is that front end weight, adding stability to your tractor, but only when needed!

- One-tank approach: filled with spray liquid it boosts overall tank capacity by 60%.

- Two-tank approach: filled with two different tank mixes, the front and rear tanks can be used as two independent spray tanks.

- Reservoir approach: filled with clean water the iXtra front tank can be used as a reservoir for later use, for example in another field or crop.

Easy to Fit, Simple to Unhitch

The iXtra front tank used the functions of the iXter B sprayer when filling and spraying. This avoids the need for a separate induction hopper or spray pump for the front tank. Without a front PTO shaft or hydraulic hoses, hitching and unhitching the iXtra is extremely simple: it uses only two hoses with KAMlock connections and an electric cable - it really is that simple!

iXspray - user interface

The Kverneland mounted sprayer is 100% ISOBUS compatible as standard, which means easy plug and play with the IsoMatch Tellus GO+ or PRO or any other AEF certified terminal. The innovative iXspray hardware and software with intuitive touch interface guarantees an user friendly operation of the sprayer. iXspray is full of nice features to make the operators life easy, save time and avoid mistakes in a busy working season, for example pre-sets for spray jobs and boom configuration can be configured easily.

Only spray when it is needed

Increase the environmental protection by only spray when it is needed with the new SpotSpray application within the iXspray software on the IsoMatch Tellus terminal in combination with the Kverneland sprayer !

Optimal Crop Protection

The SpotSpray application is based on a predefined prescription map with zero application rates. These prescription maps can be made in a similar way as the Variable Rate Application (VRA) prescription maps, in combination the SpotSpray application the sprayer shuts on and off. This is done based on the predefined sections in the control terminal and can even be done with normal section valves on the sprayer. Only designated spots are sprayed, which is particularly helpful when targeting weed spots, thistles, wet areas, non-germinated areas and areas with soil problems.

Another benefit is that based on the area of the spots in the VRA map, it is easy to see exactly how much spray liquid is required in the sprayer. Capacity is also increased as more hectares or fields can be covered with one tank of spray liquid.

With a relatively small investment in the SpotSpray license on the IsoMatch Tellus terminal, the return on investment is high, due to saving time and money. With this, spot spraying becomes accessible for all famers and contractors.

With SpotSpray costs can be saved by reducing the spray liquid to be used and preserve healthy crop from unnecessary treatment. This also means less crop damage.

Automatic filling an iXter B-iXtra sprayer combination

Kverneland TwinFill is a combined filling functionality for the iXtra front tank in combination with the iXter B rear mounted sprayer.

Always the perfect concentration

TwinFill is an automatic filling program that lets the operator fill his product in one go, for both the front and rear tank, without the disadvantage of unknown mixing time. The software takes care that the spray liquid is split and transferred to the front and rear tank with the correct volume and equal concentration. After, both tanks are filled with clean water to the required level, the same concentration is reached in both tanks. TwinFill is especially beneficial for medium sized arable farmers, vegetable farmers and contractors in mixed farming areas. The operator can simply fill all of the products in one step to the total required tank volume of the two tanks together or just enter the number of hectares to be sprayed, without having to measure all of the products twice and in different amounts and fill the tanks separately! With TwinFill the operator can immediately start the spray job, because the mixture in both tanks is perfectly diluted and ready for use - and also from start to finish for the complete spray job. There is also no waste of clean water or spray liquid, because it is exactly calculated upfront how much water or spray liquid is needed.

Multi-Tank-Management

The iXter B-iXtra combination still keeps its distinctive feature to have a multi-tank usage with two different spray mixes in front and rear tank for different applications or for storage of clean water for later use or to prepare another mixture at another moment at another place.

Technical specifications

Technical specifications

Download brochure| iXter B | |||||

|---|---|---|---|---|---|

| Nominal tank volume (l) | 1000 | 1300 | 1600 | 1800 | |

| Maximum tank volume (l) | 1100 | 1450 | 1800 | 2000 | |

| Chemical inductor (l) | 30 | 30 | 30 | 30 | |

| Clean water tank (l) | 180 | 180 | 180 | 180 | |

| Hand wash tank (l) | 18 | 18 | 18 | 18 | |

| Spray boom (m) | HOSA 15/HC 18-30 | HOSA 15/HC 18-30 | HOSA 15/HC 18-30 | HOSA 15/HC 18-30 | |

| Pumps (l/min) | 150/200/260 | 150/200/260 | 150/200/260 | 150/200/260 | |

| iXclean | iXclean Comfort/iXclean Pro | iXclean Comfort/iXclean Pro | iXclean Comfort/iXclean Pro | iXclean Comfort/iXclean Pro | |

| Controls for ISOBUS Electronics | IsoMatch Tellus PRO/GO+ or any other ISOBUS terminal | IsoMatch Tellus PRO/GO+ or ISOBUS terminal | IsoMatch Tellus PRO/GO+ or any other ISOBUS terminal | IsoMatch Tellus PRO/GO+ or any other ISOBUS terminal |

Technical specifications

Technical specifications

Download brochureiXter |

B10 |

B13 |

B16 |

B18 |

Nominal tank capacity |

1000 litres |

1300 litres |

1600 litres |

1800 litres |

Maximum tank capacity |

1100 litres |

1450 litres |

1800 litres |

2000 litres |

Chemical inductor |

30 litres |

|||

Clean water tank |

180 litres |

|||

Hand wash tank |

18 litres |

|||

Pumps |

150/200/260 (l/min) |

|||

Regulation systems |

IsoMatch Tellus PRO, IsoMatch Tellus GO+ or any other ISOBUS terminal - possible in combination with IsoMatch Grip |

|||

iXclean |

iXclean Comfort or iXclean Pro |

|||