Monopill rigid

With Monopill you can rely on a perfect execution.

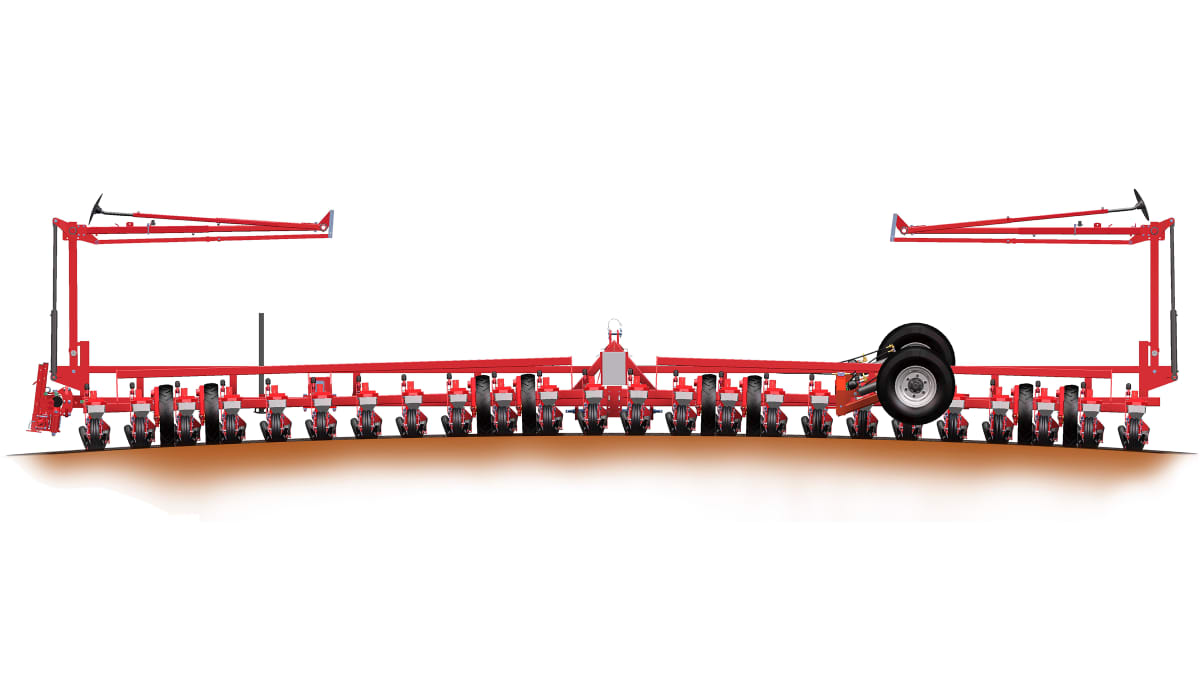

The Kverneland Monopill or Monopill e-drive II is the mechanical precision drill for beet, rape and chicory.

Highlights

- Most precise seed placement

- Even depth control by parallelogram

- Half-width shut-off and opto-electronic control

- Individual sowing units can be switched off

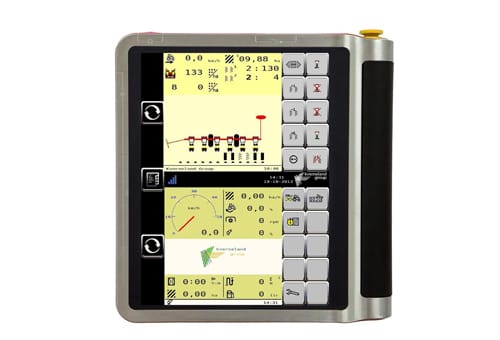

- ISOBUS Intelligence with Monopill e-drive II

Description

The MONOPILL has been designed for professional precision drilling of beet, rape and chicory. Depending on the soil type and soil condition, four different sowing rows with according equipment are available. Even under the most difficult conditions the parallelogram mounting of the sowing units guarantee precise depth control.

The Monopill ensures perfect seed placement in conventional and mulch conditions. With e-drive II each sowing unit is driven electrical individually via an electric motor. The sowing distances are infinitely adjustable on the move and can be switched off individually. The rigid end tow toolbars are available in working widths of 6m, 9m and 12 m.

Highlights

- Infinite adjustment of sowing distances from 12.5 to 25cm, optimising seed populations to soil type within the same field from the tractor cab.

- Multi choice integrated tramlining and pre-emergence marking systems (optional).

- Ability to increase plant population in the rows adjacent to the tramlines.

- Half-width shut-off and opto-electronic control for seed counting as standard for e-drive II.

- Individual sowing units can be switched off. Ideal, for example, when sowing in the corner of awkward shaped fields.

- Safety through constant control: the electronics permanently monitor all operating functions of each sowing unit constantly displaying the "real time" data on the in cab terminal.

- ISOBUS Intelligence with Monopill e-drive II

Features

Features

- The rigid end-tow toolbars are available in working widths of 3m, 6m, 9m and 12m.

- The convenient and time saving parallel hydraulic folding is available in 6 m and 9 m toolbar versions.

- The transport width of all Monopill & Monopill e-drive II models is a maximum of 3 metres.

- The optional pre-emergence markers assist first spraying operations before seed emergence.

The sowing units – like the whole machine – are modular in design

- The basic element always remains the same and the equipment can be varied according to individual requirements.

- For mulch seeding, the front Farmflex wheel is simply replaced with a double cutting disc equipped with side zero pressure tyres. The trailing coulter draws a clean seed furrow for precise seed placement.

- The Monopill can also be used for sowing rape and chicory, this allows for the extended use of the machine, earning an improved pay back of the machine cost.

- Precision-drilled rape is generally sown in row widths of 45cm. This row distance allows the use of mechanical seeding machines. Down the row spacing will vary depending on location and variety between 5 and 8 cm.

- Electric drive with control directly from the tractor cab using ISOBUS technology.

- The seeding heart is driven directly by a variable speed electric gear motor. There are no mechanical drive parts.

- Infinite adjustment of sowing distances from 12.5 to 25cm, optimising seed populations to soil type with the same field from the tractor cab.

- Multi-choice integrated tramlining and pre-emergence marking systems (optional).

- Ability to increase plant populatioon in rows adjacent to the tramlines

- Individual sowing units can be switched off.

- Opto-electronic control for seed counting.

The cultivation of sugar beet requires special care and the right supply of nutrients. In this respect, the application of micro granule and micro fertiliser whilst seeding plays an important role for early crop development.

micro-drill

Each unit of the micro-drill has been designed to supply three sowing units and offers a hopper capacity of 35 liters. It is electrically driven and ISOBUS controlled. The metering device consists of a wear-resistant plastic housing and exchangeable cell wheels made of stainless steel which ensure precise metering of different micro granules. Application rates from 2kg up to 25kg/ha are possible.

Emission control

The advantage for the environment: the granulate falls freely into the seed furrow without air support, minimising the emission of dust and complying with the current guidelines for emission control for any granulates applied.

Precision Farming

The comfortable, fully ISOBUS, integrated control system allows the adaption of the stop and start points of the seed row. This ensures precise shutting on and off at the end of the field (without overlaps or faults).

Operator safety

The engineers’ focus has been to increase operator safety by easy and safe handling. Therefore, the operator is able to exchange the cell wheels even when the hoppers are full of granule. There is no need to empty them first, reducing the operator’s risk of being in direct contact with the granules.

The Kverneland micro dill has been approved by the Julius Kühn Institute (Institute for Application Techniques in Plant Protection) (Reference G 2196).

The Kverneland micro-drill is available for Monopill e-drive II and Unicorn e-drive II.

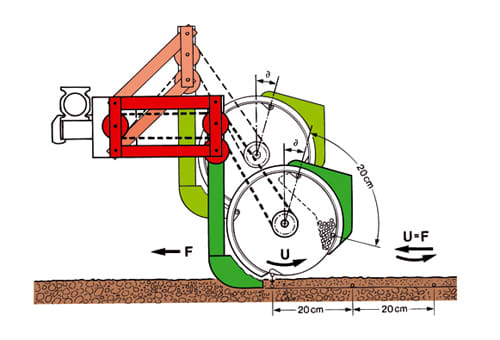

- The seed disc is rotating through the second patented seed chamber

- The disc picks only one seed at a time, additional seeds are wiped off

- Due to the centrifugal force, the seed remains in the seed cell throughout its rotation

- With the seeding heart positioned deep inside the seeding coulter, the seed drop height is only 3cm

- The lowest drop height on the market, plus zero speed effect sowing provide precise placement.

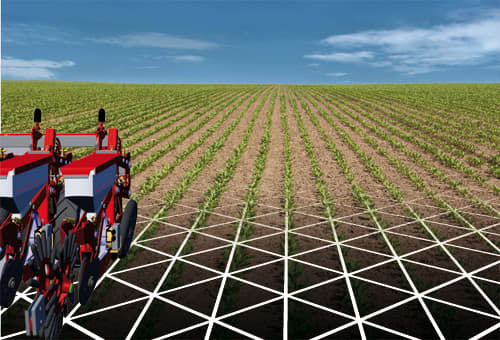

GEOSEED - Precision at high end

GEOSEED is the precise synchronization of seed placement across the full working width of the machine. This ensures that seeds are distributed evenly, achieving an optimal pattern—either parallel or diamond-shaped—across the soil surface. The positive effects of this technology are far-reaching. By enhancing seed distribution, GEOSEED maximizes the efficient use of key resources such as nutrients, water, and sunlight, fostering optimal plant growth. Additionally, this uniform planting pattern helps reduce the risks of wind and water erosion, as the even distribution of plants improves soil structure and coverage, leading to better water retention and minimizing soil degradation.

GEOCONTROL - Cost saving with immediate payback

Seeding with GPS and GEOCONTROL in combination with an electric driven precision drill is a major step towards precision and cost saving. These machines are all equipped with ISOBUS technology which with the help of the IsoMatch Tellus terminal, can be easily controlled.

Each electric driven seeding element, in combination with GPS and GEOCONTROL, is automatically switched on or off in exactly the right place, ensuring there is no overlap with any row that has already been seeded. This is especially handy in triangular fields, on curved or irregular shaped headlands.

- The rigid end-tow toolbars are available in working widths of 3m, 6m, 9m and 12m.

- The convenient and time saving parallel hydraulic folding is available in 6 m and 9 m toolbar versions.

- The transport width of all Monopill & Monopill e-drive II models is a maximum of 3 metres.

- The optional pre-emergence markers assist first spraying operations before seed emergence.

The sowing units – like the whole machine – are modular in design

- The basic element always remains the same and the equipment can be varied according to individual requirements.

- For mulch seeding, the front Farmflex wheel is simply replaced with a double cutting disc equipped with side zero pressure tyres. The trailing coulter draws a clean seed furrow for precise seed placement.

- The Monopill can also be used for sowing rape and chicory, this allows for the extended use of the machine, earning an improved pay back of the machine cost.

- Precision-drilled rape is generally sown in row widths of 45cm. This row distance allows the use of mechanical seeding machines. Down the row spacing will vary depending on location and variety between 5 and 8 cm.

- The seed disc is rotating through the second patented seed chamber

- The disc picks only one seed at a time, additional seeds are wiped off

- Due to the centrifugal force, the seed remains in the seed cell throughout its rotation

- With the seeding heart positioned deep inside the seeding coulter, the seed drop height is only 3cm

- The lowest drop height on the market, plus zero speed effect sowing provide precise placement.

- Electric drive with control directly from the tractor cab using ISOBUS technology.

- The seeding heart is driven directly by a variable speed electric gear motor. There are no mechanical drive parts.

- Infinite adjustment of sowing distances from 12.5 to 25cm, optimising seed populations to soil type with the same field from the tractor cab.

- Multi-choice integrated tramlining and pre-emergence marking systems (optional).

- Ability to increase plant populatioon in rows adjacent to the tramlines

- Individual sowing units can be switched off.

- Opto-electronic control for seed counting.

The cultivation of sugar beet requires special care and the right supply of nutrients. In this respect, the application of micro granule and micro fertiliser whilst seeding plays an important role for early crop development.

micro-drill

Each unit of the micro-drill has been designed to supply three sowing units and offers a hopper capacity of 35 liters. It is electrically driven and ISOBUS controlled. The metering device consists of a wear-resistant plastic housing and exchangeable cell wheels made of stainless steel which ensure precise metering of different micro granules. Application rates from 2kg up to 25kg/ha are possible.

Emission control

The advantage for the environment: the granulate falls freely into the seed furrow without air support, minimising the emission of dust and complying with the current guidelines for emission control for any granulates applied.

Precision Farming

The comfortable, fully ISOBUS, integrated control system allows the adaption of the stop and start points of the seed row. This ensures precise shutting on and off at the end of the field (without overlaps or faults).

Operator safety

The engineers’ focus has been to increase operator safety by easy and safe handling. Therefore, the operator is able to exchange the cell wheels even when the hoppers are full of granule. There is no need to empty them first, reducing the operator’s risk of being in direct contact with the granules.

The Kverneland micro dill has been approved by the Julius Kühn Institute (Institute for Application Techniques in Plant Protection) (Reference G 2196).

The Kverneland micro-drill is available for Monopill e-drive II and Unicorn e-drive II.

GEOCONTROL - Cost saving with immediate payback

Seeding with GPS and GEOCONTROL in combination with an electric driven precision drill is a major step towards precision and cost saving. These machines are all equipped with ISOBUS technology which with the help of the Tellus terminal, can be easily controlled.

Each electric driven seeding element, in combination with GPS and GEOCONTROL, is automatically switched on or off in exactly the right place, ensuring there is no overlap with any row that has already been seeded. This is especially handy in triangular fields, on curved or irregular shaped headlands.

GEOSEED - Precision at high end

GEOSEED is the precise synchronization of seed placement across the full working width of the machine. This ensures that seeds are distributed evenly, achieving an optimal pattern—either parallel or diamond-shaped—across the soil surface. The positive effects of this technology are far-reaching. By enhancing seed distribution, GEOSEED maximizes the efficient use of key resources such as nutrients, water, and sunlight, fostering optimal plant growth. Additionally, this uniform planting pattern helps reduce the risks of wind and water erosion, as the even distribution of plants improves soil structure and coverage, leading to better water retention and minimizing soil degradation.

Technical specifications

Technical specifications

Download brochure| Model | Monopill | Monopill | Monopill | Monopill | |

|---|---|---|---|---|---|

| Frame | rigid | rigid | rigid | rigid | |

| Working width (m) | 3.0 | 6.0 | 9.0 | 12.0 | |

| No. of rows | 6 | 12 | 18 | 24 | |

| Row width (cm) | 45/50 | 45/50 | 45/50 | 45/50 | |

| Transport width (m) | 3.0 | 3.0 2) | 3.0 2) | 3.0 2) | |

| Weight of basic version (kg) | 400 | 910 | 1,750 | 2,800 | |

| Mechanic drive with 7 gear lever gearbox | Standard | Standard | Standard | - | |

| e-drive II, ready for GEOSEED® | Standard | Standard | Standard | Standard | |

| IsoMatch Tellus PRO | Option | Option | Option | Option | |

| IsoMatch Tellus GO+ | Option | Option | Option | Option | |

| Visus | Option | Option | Option | - | |

| Radar (only with e-drive II) | Standard | Standard | Standard | Standard | |

| Linkage | CAT. II | CAT. II | CAT. III | CAT. III | |

| Tyres 5.00x15 (no.) | Standard (2) | Standard (2) | Standard (4) | Standard (8) | |

| Hydraulically operated track marker arms | Standard | Standard | Standard | Standard | |

| Pre-emergence markers | Option | Option 1) | Option 1) | Option 1) | |

| Road light kit | Option | Option | Option | Option | |

| Track eradicator (2x2 tines) | Option | Option | Option | Option | |

| Frame ballasting kit | Option | Option | - | - | |

| Lengthwise transport device | - | Option | Option | Option | |

| Electric driven microgranule applicator micro-dril | Option | Option | Option | Option | |

| Microgranule hopper volume (l) | 35 | 35 | 35 | 35 | |

| No. of microgranule hoppers | 2 | 4 | 6 | 8 |

1) Risk of collision of pre-emergency marker and lengthwise transport devise

2) Lengthwise transport device

Technical specifications

Technical specifications

Download brochureWorking width |

Row width |

Weight |

|

Monopill 6 row rigid |

3.0m |

45/50 |

400 |

Monopill 12 row rigid |

6.0m |

45/50 |

910 |

Monopill 18 row rigid |

9.0m |

45/50 |

1750 |

Monopill 24 row rigid |

12.0m |

45/50 |

2800 |

Monopill 12 row PH |

6.0m |

45/50 |

1250 |

Monopill 18 row PH |

9.0m |

45/50 |

2180 |

1) Risk of collision of pre-emergency marker and lengthwise transport devise

2) Lengthwise transport device