f-drill CB F

Effective sowing – with flexibility ready for the future

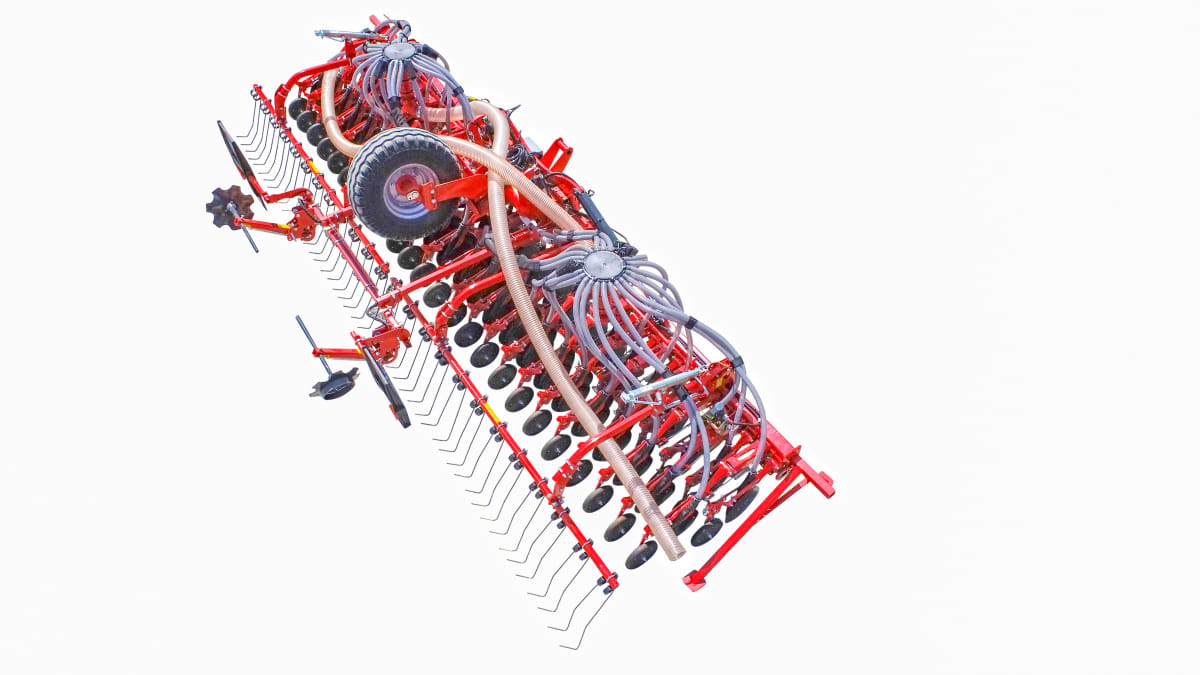

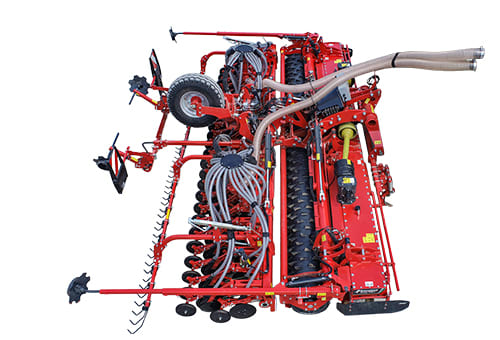

The modular structure of the folding coulter bar of the Kverneland f-drill ensures an even weight distribution across the machine arrangement providing the maximum balance. The dissolved design offers utmost flexibility and improves safety and manoeuvrability.

Highlights

- Maximum balance of the tractor

- Versatile combination

- Precision and high work output

- Adjustable seed rate from the cab

- Dissolved modular structure for utmost flexibility

Description

The folding coulterbar of the f-drill has been designed to give farmers and contractors utmost flexibility as it adapts to all kind of farming systems. The folding coulterbar complements the f-drill model range and is available in 4.0m, 4.5m, 5.0m and 6.0m working width. The row distance can be varied; from the factory, we offer 12.5 and 25.0cm. Application of seeds, the combined application of seeds and fertiliser as well as of seeds and companion crops is possible. Due to the clear design and the high level of incorporated intelligent technology, the coulterbar offers maximum ease of use and utmost flexibility.

Features

Features

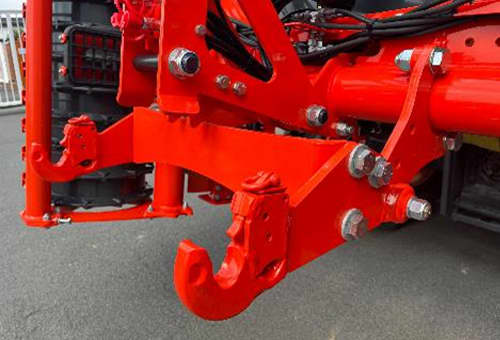

For full flexibility and to operate in seeding combination with the Kverneland front hopper, f-drill and the power harrow, Rotago F, the folding coulterbar f-drill CB F is easily connected via an independent central coulterbar connection.

- All hydraulic and electric coulterbar functions are fitted to a coupling interface for clean and easy connection

- Good overview from the tractor cab

- The hydraulic top link connection controls the integrated seed depth adjustment

The rigid f-drill CB in 3.0m / 3.5m / 4.0m and the folding f-drill CB F in 4.0m working width can be also fitted with double entry CX-II coulters for additional ways of sowing. With the coulter CX-II double-entry, fertiliser or a second crop is placed together with the seeds in just one working pass. This is especially suitable e.g. for phosphoric fertiliser to support the initial germination and development of the plants in the most efficient way. Due to an extra outlet of the CX-II coulter double entry, various combinations are possible:

- two types of seeds,

- one type of seed and one type of fertiliser or

- one type of seed combined with e.g. slug pellets

- one type of seed.

The flexible and individual depth setting of each CX-II coulter double entry allows different sowing depth even within one working width. This is extremely important when sowing two different products in one pass e.g. rape at a shallow depth and companion crops like beans deeper.

The CX-II disc coulter from Kverneland not only guarantees smoother running but also exact seed placement. The flatter cutting angle of only 5.4° of the steel disc requires less pulling power to reach a constant seeding depth of up to 6cm.

Due to the combination of the steel disc with a diameter of 325mm and the flexible plastic disc, there is no need for independent scrapers, saving the cost for expensive wearing parts. In addition the coulter is completely maintenance-free!

Up to 50kg coulter pressure can be achieved by a pre-loaded spring. Safe operation is ensured when working with high working speeds and high quantities of plant residues on the soil surface. An inter-row coulter spacing of 445mm for maximum clearance and the following press wheel (standard equipment) ensure an optimum seed/soil contact in all conditions. The press wheels can be set in fixed, floating or lifted position in order to be able to adapt quickly to changing weather, soil or working conditions.

The CX-II coulter is also available as light edition without press wheel which reduces the weight and length of the coulterbar. This will allow to operate the seeding combination also with lower lifting capacity of the tractor.

Easy connection with electronics – intelligent, operator-friendly

The ISOBUS e-com software’s “plug and play” compatibility enables the rigid coulterbar f-drill CB, the folding coulterbar f-drill CB F, the power harrow Rotago F and the front hopper f-drill to be connected to any ISOBUS compatible tractor, for fully functional use by the tractor’s own terminal or alternatively, Kverneland’s IsoMatch Tellus Pro or the IsoMatch Tellus GO+.

The folding coulterbar of the seeding combination Kverneland f-drill front hopper and power harrow, Rotago F, is equipped with a support wheel for road transport.

- The support wheel can be mounted on the power harrow or to the attached coulter bar

- The constant supporting force on the wheel ensures smooth road transport, due to the hydraulic suspension

- No uncoupling of the top linkage for transport necessary

- Passive steering

When driving backward, the support wheel must be lifted.

The folding coulterbar f-drill CB F is equipped with a following harrow to finish the job. The S-shaped harrow ensures an optimum covering of the seeds. The working intensity can be set by the step less pressure adjustment.

Technical specifications

Technical specifications

Download brochureModel |

f-drill CB F |

f-drill CB F |

f-drill CB F |

f-drill CB F |

Working width (m) |

4.00 |

4.50 |

5.00 |

6.00 |

Coulter type |

CX-II or CX-II-double entry |

CX-II |

CX-II |

CX-II |

Press wheel |

with or without |

with or without |

with or without |

with or without |

No. of coulters |

32/16 |

36/18 |

40/20 |

48/24 |

Row distance (cm) |

12.5 or 25.0 |

12.5 or 25.0 |

12.5 or 25.0 |

12.5, 15,0 or 25.0 |

No. of distribution tubes |

1 or 2 |

1 |

2 |

2 |

Ø of the distribution system (mm) |

1 x 135 |

1 x 135 |

2 x 110 |

2 x 110 |