Win a Kverneland disc spreader valued at €12,500 and save thousands!

Don't miss this opportunity to cut your input cost on spreading.

Winner will be announced this month.

To kick off 2022 and to provide some much needed relief to farmers struggling with fertiliser costs, Kverneland Group Ireland are hosting a competition.

Check out below the walk around video with Leonard Hovenden on the Exacta Fertiliser Disc spreader range or read up below on the highlighted features of the Kverneland Exacta spreaders.

Too much dust will make the tractor and spreader dirty and pollute the air. Fertiliser dust is a loss! Too much grit or granules that are too big might damage sensitive crops like spinach, leeks or sugar beet for example. You can use the granular size box even when buying fertiliser to be able to determine the quality of the fertiliser.

All of our fertiliser spreaders are delivered with a granular size box as standard equipment. The granule size box is the most important tool, which always has to be used when the spreader is being adjusted before spreading.

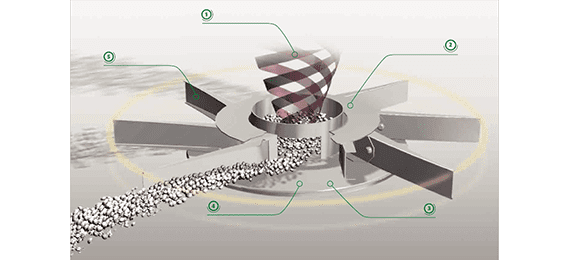

Kverneland Exacta fertiliser spreaders have an unique feature: the CentreFlow spreading system. This initial smooth acceleration of the fertiliser prevents fragmentation of the granules due to the impact of the vanes. The adjustable discharge point allows adaptation of settings of the physical fertiliser properties. Due to the gentle handling of the fertiliser the spreading characteristics of the product are maintained. The CentreFlow spreading system is designed for maximum performance.

Large 8 vane discs allow 9m to 54 m spread widths. Double overland spread pattern gives maximal accuracy. The 8 vanes per disc ensure a continues flow of fertiliser to the field. This is important when driving higher speeds and spreading larger quantities.

The weighing system on Kverneland Exacta CL and TL GEOSPREAD models consists of 4 weighing cells, each with a capacity of 5 tonnes, positioned at the corners of the hopper. All GEOSPREAD models are uniquely equipped with a reference sensor which automatically corrects the measurements for slopes or shocks. The weighing system with automatic calibration compares the actual fertiliser flow with the expected fertiliser flow (based on the area covered) and adjusts the dosing automatically in case deviations occur. This feature will help to prevent over and under dosing resulting in better yields and saving of fertiliser.