Does your Drill have what a Kverneland Drill has?

e-drill integrated seeding solutions

Kverneland's complete range of pneumatic drills cover the gamut of farmer requirements; from entry level DA drills to top of the range one pass systems like the e-drill that allow one pass seeding and harrowing or alternatively one pass grain and fertiliser sowing with the split hopper on the e-drill maxi plus. The plus refers to the one pass seeding and fertilising capability.

Let's take a look at some of Kverneland's unique features below.

The CX-II coulter is precise, and very easy to set up. With the double entry CX-II coulter two sorts of seeds/fertiliser is laid precise in the seeding row in just one pass. The flat cutting angle of the steel disc requires less coulter pressure to reach a constant seeding depth of up to 6cm.

The press wheels ensure the optimum coulter-soil contact. Important for a constant seed depth is the distance between the coulter and the press wheel. The close coupling of the CX-II system increases the seed depth accuracy because the closer the distance the less influence on the seed depth. Three possible adjustments adapted to soil condition guarantee perfect seed placement. For level and even ground it can be set in the fixed position. In cloddy or stony conditions it is set in the flexible position to ensure smooth running and a perfect ground following. In extreme wet conditions the press wheel can be lifted out of work completely. On slightly sticky soils an optional scraper is recommended. Thanks to the combination of steel disc and flexible plastic disc, there is no need for independent scrapers. The coulter is completely maintenance free!

ELDOS is the electric driven metering device for Kverneland pneumatic seed drills. It is state-of-the-art technology for perfect seed placement.

ELDOS is steered by Kverneland e-com or e-bas software. The e-com version is fully ISOBUS compatible. The e-bas system controls the ELDOS metering device, the tramlining, the hectare metre and fan speed control. Calibration is automatic, and a range of interchangeable seed metering rotors can be swapped - even when the hopper is full - without the need for tools. Sensors monitor the metering rotors and the calibration flap and give a warning if the wrong metering rotors are accidentally installed or the flap is not closed. Double and/or missed seeding on headlands or odd-shaped fields are managed by special sensors that ensure complete functionality from the tractor cab.

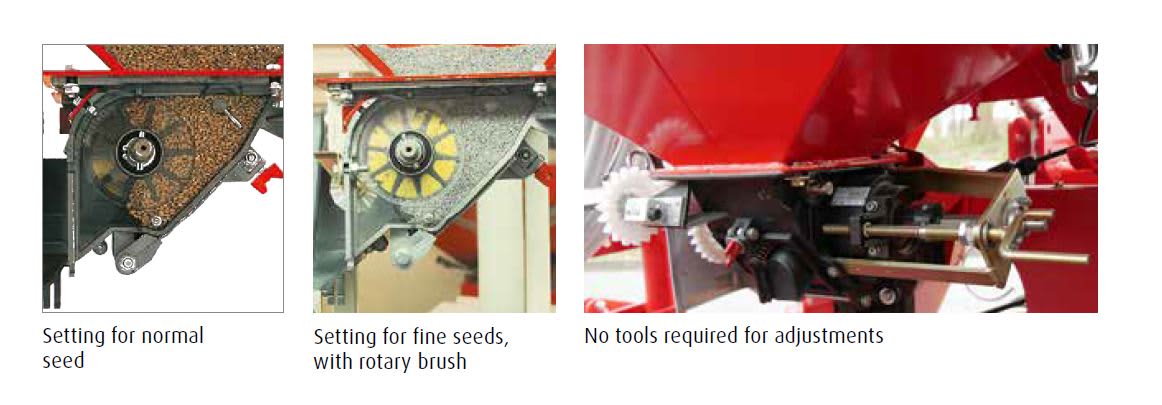

The central metering device accurately measures any desired volume of seed from 2kg/ha to 380kg/ha. For the sowing of fine seeds, e.g. rape or grass, the metering device can be infinitely adjusted to fine seed/micro metering by means of a spindle, without any need for tools. The central, totally enclosed cell wheel of the metering device accurately measures the required volume of seed and discharges it into the venturi cone where it is mixed with the air stream and then conveyed through the diffusor tube and the seed delivery hoses to the coulters.

The sowing depth can be adjusted mechanically centrally via crank or hydraulically via spacers at the two cylinders without any tools. The quadruple joint of the coulter bar ensures a constant seed application by the short and long coulters at any sowing depth. The parallelogram of the power harrow guarantees an independent adjustment of the tine depth without any impact to the sowing depth. The complete coulter bar can be lifted e.g. for the preparation of the headlands. The patented lateral position of the metering device ELDOS ensures a good and ergonomic access. This also facilitates an easy rest emptying and cleaning of the hopper. In addition the depth adjustment of the following harrow is organised centrally by a crank. The scale allows an easy control, even if the complete harrow is lifted up while a radar speed sensor records the speed in order to maintain the relevant distribution rate at the correct time.

"We struggled last autumn to get crops in with our previous drill due to constantly changing weather patterns", explains William Orr of West Mains. Therefore the family-run farming business bought a 4M e-drill maxi, sitting above a 4M NG-S power harrow which create a close-coupled combination with the tractor. The outfit arrived in time to drill 100ha of spring barley. With 300ha of combinable crops, the farms ploughs ahead of the drill. He believes the power harrow’s cracker packer provides the optimum level of consolidation directly behind the coulters. “We’re really pleased with the seed placement and germination” says William. A Tellus Go in cab terminal takes care of drill set up, with the farm yet to take advantage of ISOBUS. “That said, it’s already a very easy machine to use. Seed rolls are easy to swap and calibration is straight-forward” he adds. “I don’t have auto start/stop on the drill, so I need to allow for a little overlap.” The e-drill has done a fantastic job”. Mr Orr is so pleased with the e-drill that he plans to sow oil seed rape with it this summer. William Orr, West Mains UK.

.