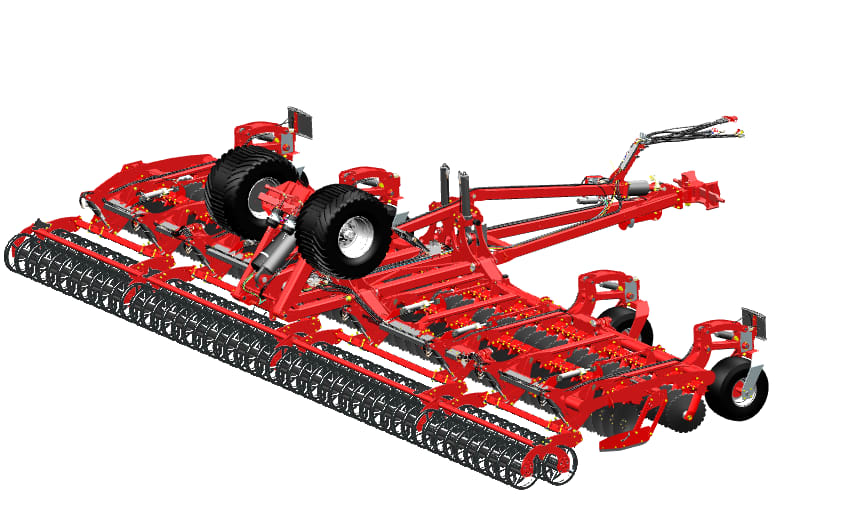

Kverneland Qualidisc 21000 T

Effective soil cultivation with high capacity and performance

With focus on sustainable and precision farming, Kverneland developed the trailed compact disc harrow, Qualidisc 21000 T, in working width of 12.25m. The Qualidisc 21000 T perfectly fits to Controlled Traffic Farming systems. The range of operations is versatile: shallow and deep cultivation (3 to 15cm), as well as seedbed preparation after ploughing.

Description

The Qualidisc 21000 T is arranged in four independently mounted frame segments. Pressure on each segment can be adjusted pair by pair via the Ground Contour System to ensure a constant pressure on the soil. Due to this unique ground following, the Qualidisc 21000 T leaves a perfectly even surface. The conical discs (Ø 600mm) are the same as on the Qualidisc Pro models ensuring a full cut and also excellent performance for catch crop incorporation. The machine operates at speeds of up to 20km/h, maintaining a full cut at a consistent working depth in all soil conditions.

Technical specifications

Technical specifications

Download brochure| Model | Qualidisc 21123 T | |

|---|---|---|

| Frame | trailed (4 segments) | |

| Working width (m) | 12.25 | |

| Transport width (m) | 2.95 (homologated version) | |

| Underbeam clearance (mm) | 810 | |

| Inter-row distcance (mm) | 900 | |

| Ground Contur System | Standard | |

| Number of discs | 98 | |

| Disc diameter - Hardness | 600×6mm - 215kg/mm2 | |

| Disc spacing (mm) - 2 disc rows | 125 | |

| Working depth (cm) | 3-15 | |

| Depth adjustment | Hydraulic by scale | |

| Linkage | Cross shaft Cat. IV, Fixe eye ⌀50mm (only with drawbar extention) | |

| Pair of star disc | Option | |

| Roller offering | Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | |

| Transport wheels | 560/60R22.5 (EU road homologation) or 710/50R26.5 | |

| Gauge wheels | 4×400/60-15.5 | |

| Frame box section | round tube diameter 180x8mm and 150x150x10 (central frame) | |

| No. of double acting valves | 2 double acting valves + LS or 1 additional for GCS | |

| Brake | hydraulic or pneumatic | |

| Total weight with Actipack (kg) | 14600 | |

| Total weight with Actipress Twin (kg) | 14800 | |

| Min. HP | 400 | |

| Max. HP | 650 |