Kverneland DL

Compact seed drill for small and medium tractors

Highlights

Low position of hopper for easy filling Hopper positioned close to tractor Easy calibration Wheels run directly in tractor tracksDescription

Compact tractor-mounted seed drill

The Kverneland DL is a compact seed drill and is the ideal machine for small and medium-sized farms. As a tractor-mounted seed drill, the DL combines compact, light design with the proven Kverneland quality.

With the compact design, the DL seed drill is mounted close to the centre of gravity, meaning the power requirement is as little as 55 kW. The DL seed drill has a working width of up to 4.5 meters. To ensure constant ground contact of the seed drill, the wheels of the DL can be easily adjusted to suit any track from 1.65. to 2.10. The DL can be fitted either with standard or flotation tyres.

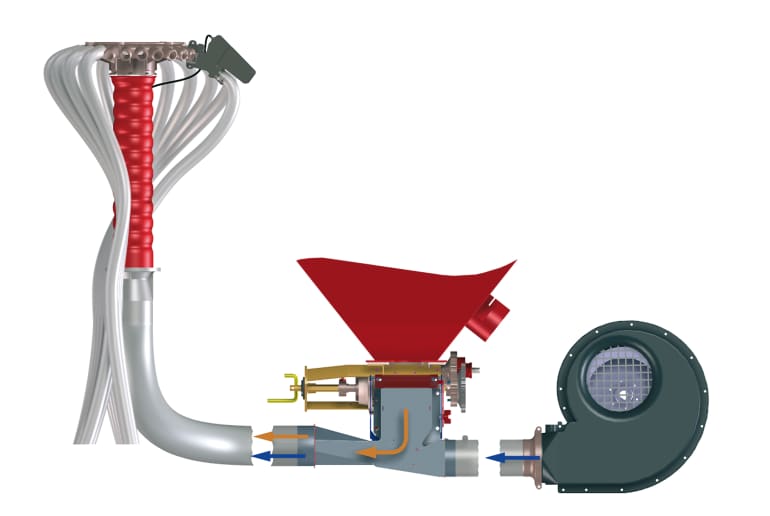

Even with its compact design, the DL pneumatic seeder has a hopper capacity of 750 litres, which can be extended to 1000 litres. For electronic control, the FGS, Signus and IsoMatch Tellus are available options.

Features

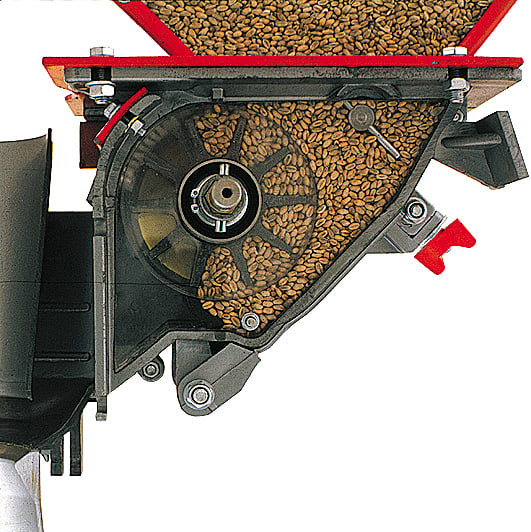

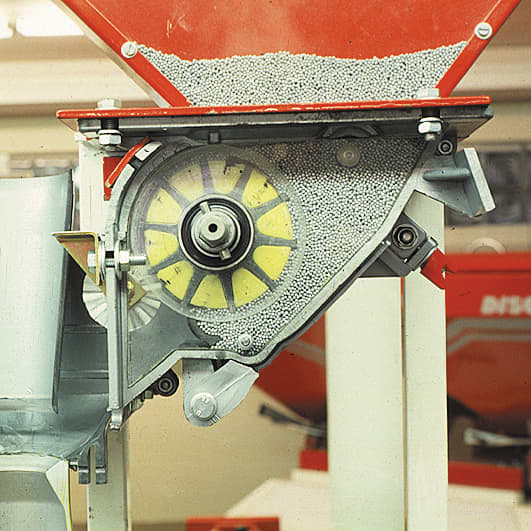

- The central metering device accurately metres any desired volume of seed from 2kg per hectare to 380kg per hectare

- For the sowing of fine seeds, e.g. rape or grass, the metering device can be infinitely adjusted to fine seed/micro-metering by means of a spindle, without any need for tools.

- The metering system is mechanically driven via the spiked landwheel running in the tilled soil.

- The metering device is centrally positioned and easily accessible under the hopper.

Apart from the well-known tramline control FGS and the Signus, the pneumatic seed drills can be equipped with the Tellus GO+ and the IsoMatch Tellus PRO.

Tellus GO+

Tellus GO+ is especially developed for controlling the machine in a simple way. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch.

IsoMatch Tellus PRO – the next generation universal ISOBUS Terminal

- Two ISOBUS interfaces in one terminal

- Multifunctional ergonomic design

- ISOBUS Shortcut Button (ICB)

With this new terminal you can work all the way as a PRO. The maximum working range for the task controller IsoMatch GEOCONTROL is increased from 2 km to maximum 10 km from the starting point. Thus even extremely big fields are handled in a full professional way. The new high brightness screen increases operator comfort. Visibility is increased during the day and dimmed to just a glowing display in dark conditions.

- The central, totally enclosed cell wheel of the metering device accurately measures the required volume of seed and discharges it into the venturi cone where it is mixed with the air stream and then conveyed through the diffuser tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

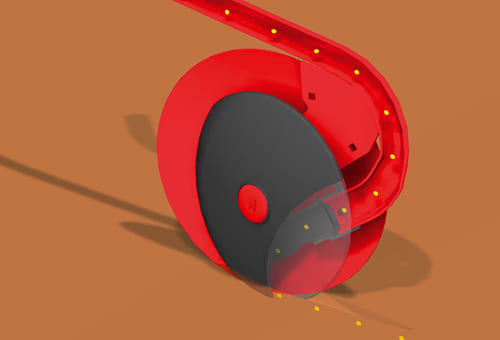

The CX disc coulter for optimum seed placement

- The CX disc coulter ensures exact seed placement under both wet and dry conditions

- Due to the combination of convex steel disc and flexible plastic disc, there is no need for independent scrapers saving the costs for expensive wearing parts.

- The convex steel disc forms a clean and clear furrow with light recompaction. The narrow profile allows higher working speed and the convex form of the disc ensures good depth control.

- The flexible plastic disc keeps the furrow open for exact seed placement. It cleans the steel disc and helps prevent sticking and blocking.

- Narrow and wide press wheels are available for special seeding conditions. These press wheels can be fully lifted in case of changing weather conditions.

Technical specifications

Technical specifications

Download brochureWorking Width |

Hopper Capacity |

Weight |

|

DL |

3.0m - 4.0m |

750 litres standard plus optional extension of 250 litres |

435 - 560kg |

DL |

4.5m |

1000 litres |

560kg |