Kverneland Optima TFmaxi

Pneumatic precision drill with a working width of 12m for best precision seeding and large capacity

Highlights

Most precise seed placement Maximum performance with 12m working width Fully integrated fertiliser spreader Fully ISOBUS-compliant 50 km/h transport on the roadDescription

The Kverneland Optima is the universal pneumatic precision drill for maize, sunflowers, field beans, unpelleted beet, pelleted beet, dwarf beans, soya beans, peas, and many other types of seeds, ready for mulch or conventional sowing.

Within this product group of the well-proven Kverneland Optima precision drills, the Optima TFmaxi is the large trailed model with a working width of 12m, thus especially adjusted for today’s modern large-scale farms and contractors. It offers a unique performance with up to 100 hectare in one day – reducing the costs for the tractor and the driver.

The Optima TFmaxi is equipped with a 4000l fertiliser hopper and 16 seed hoppers of 55l each. Despite the large capacity, the pulling force is still low - starting from 240hp

The Optima TFmaxi combines high performance technology with maximum user friendliness. The machine’s clear and logical layout together with the high level of intelligent technology offer the user maximum ease of use, from set-up and filling, to transport and seeding operation

Features

- The Optima TFmaxi is based on a stable, telescopic frame of 250 x 450mm main chassis. The complete control umbilical for electronics and hydraulics is safely positioned inside the frame.

- Due to the hydraulic drive via pto shaft being mounted at the cross shaft, excellent manoeuvrability has been achieved.

- A turning angel of 80° allows seamless coverage of the field with tight headland turns. The standard cross shaft is Cat. 3N, alternatively Cat. 4N is an option, both guaranteeing high stability.

- When converting the machine into transport position the frame is extended so that the two wing sections are folded parallel to the main frame. When in the transport position the overall width is 3.0 metre

- 4.000 litre capacity

Opening: 2.31 x 2.45m; Height: 3.49m - Loading step for a safe access to the hopper

- Slide for easy and quick emptying of remaining seeds

- Hopper low level sensor adjustable in height

- Water and dust-proof hopper cover made of steel with an easy folding mechanism

- Optional filling auger with a filling height of 750mm

- Automatic unfolding of the filling auger when the machine is in working position

For mulch and conventional sowing

- Optimal depth control even under extreme conditions, due to the heavy basic weight of the sowing unit with the possibility to add additional pressure (up to 100kg) onto each individual sowing unit via the spring-loaded system.

- Effective ground contour following, due to the large lateral depth control by open gauge wheels (Ø410mm, width 120mm).

- Precise seed placement by the small coulter which forms a clean furrow. Light re-compaction and seed covering is done by the intermediate press wheel (as option: heavy stainless steel) and the multi-adjustable V-press wheel – to ensure maximum field emergence.

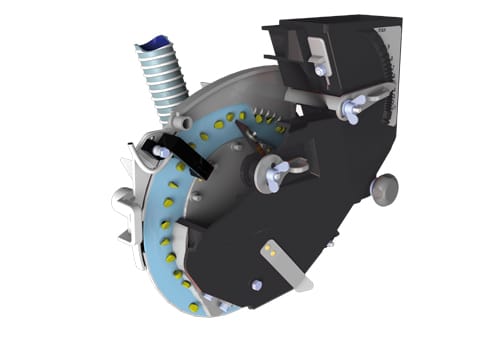

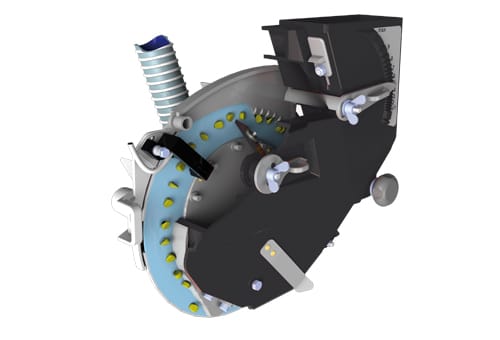

Seeding heart without seals for HD-II

- The patented seeding heart by Kverneland has reduced maintenance costs to a minimum.

- No friction, no wear, low drive torque, minimum maintenance: The seed disc rotates in the seeding heart together with the vacuum chamber. This seeding drum is connected to the vacuum fan via a hollow shaft.

- This seed heart principal results in no loss of vacuum, and therefore a low vacuum requirement

Seeding heart without seals

- The patented seeding heart by Kverneland has reduced maintenance costs to a minimum

- No friction, no wear, low drive torque, minimum maintenance: The seed disc rotates in the seeding heart together with the vacuum chamber. This seeding drum is connected to the vacuum fan via a hollow shaft

- This seed heart principal results in no loss of vacuum, and therefore a low vacuum requirement

IsoMatch GEOCONTROL - Cost saving with immediate payback

Seeding with GPS and GEOCONTROL in combination with an electric driven precision drill is a major step towards precision and cost saving. These machines are all equipped with ISOBUS technology which with the help of the IsoMatch Tellus terminal, can be easily controlled.

Each electric driven seeding element, in combination with GPS and GEOCONTROL, is automatically switched on or off in exactly the right place, ensuring there is no overlap with any row that has already been seeded. This is especially handy in triangular fields, on curved or irregular shaped headlands.

Technical specifications

Technical specifications

Download brochureWorking width / transport width |

12.00m (75cm) / < 3.00m |

Transport length / transport height / transport speed |

9.80m / 3.48m/ 50km/h (max. transport loading 2 t) |

Row width |

70cm, 75cm, 80cm |

Working wheels and transport wheels |

6 x 12.5/80 and 2 x 560/60 |